Power of Diagrams in the Manufacturing Industry

EdrawMax accelerates the growth and production of government and enterprise clients around the world.

Challenges and Problems You Are Facing in Work or Study

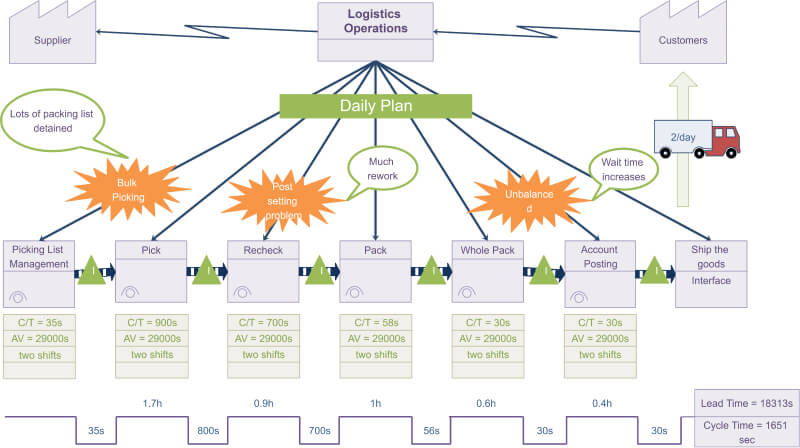

Communication supports coordinating the efforts of a team throughout the manufacturing process. Better communication between team members and stakeholders helps in reducing risks, improves productivity, cohesion, and engagement.

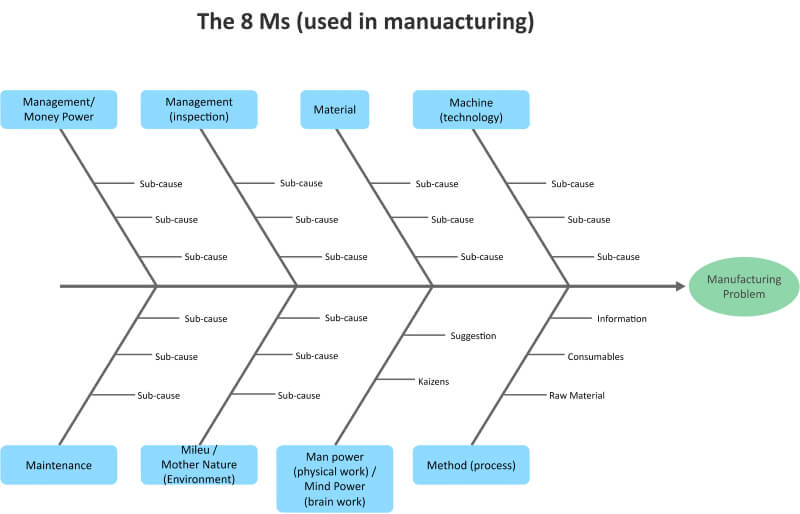

A well-designed diagram of plant, process, and machines supports early fault detection and root cause isolation. When the diagrams are not present, the process of fault detection depends on hit and trial.

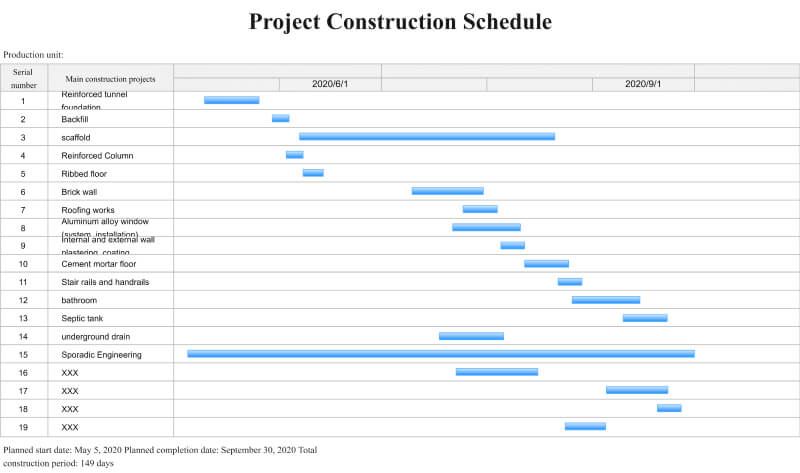

Proper planning and design are key factors contributing to high efficiency. Diagrams improve efficiency because there is standard job distribution, audit, an emergency plan, and also prediction of faults to preempt the undesirable events.

Source:EdrawMax Template Community

Source:EdrawMax

Source:EdrawMax Online

Ready to Upgrade Your Business?

Our team will be happy to discuss plans, products, and services with you.

Contact Sales For Individuals

EdrawMax Helps You Design Like A Pro | EdrawMax Customer Story

EdrawMax Supports Strategic Planning | EdrawMax Customer Story