Manufacturing Process Flowchart Complete Guide

Edraw Content Team

Do You Want to Make Your Manufacturing Process Flowchart?

EdrawMax specializes in diagramming and visualizing. Learn from this manufacturing process flowchart complete guide to know everything about the manufacturing process flowchart. Just try it free now!

Given the innate complexity of some manufacturing processes, managers constantly look for ways to adequately explain each process component to the people involved to avoid production mistakes. However, verbal communication is, more often than not, insufficient to explain everything. With flowcharts—tool that can be used to create easy-to-understand visual aids for processes.

Manufacturing process flowcharts are one of the tools that are commonly used in process analysis. Manufacturing personnel, especially supervisors and managers, use this flowchart to highlight the sequence and priority of operations on the production floor. This article further discusses the benefits of manufacturing process flowcharts and provides tips on how to efficiently create one.

1. What is a Manufacturing Process Flowchart?

As the name implies, a manufacturing process flowchart is a type of diagram that specifically shows the sequence of steps in a manufacturing process. In the past, people could only draw manufacturing process flowcharts by hand. With the advent of technology, numerous software like Excel can now be utilized to produce standard flowcharts and even customize one to clearly present the activities in a process, as well as the inputs and expected outputs.

The steps in a manufacturing process flowchart template are represented by specific shapes and symbols. To indicate the flow of the operation, the shapes and symbols are connected by lines and arrows. This design logic provides a quick and simple reference to the users, reducing the risk of misunderstanding and improving time management on the production floor.

2. When to Use Manufacturing Process Flowcharts?

Manufacturing process flowcharts are commonly used by managers to simplify the training and orientation of production employees. In addition, this type of diagram is particularly useful in the following scenarios:

- Explaining how to perform a process

- Identifying areas for improvement

- Promoting communication and collaboration among the people/departments involved with the same process

- Documenting a process

- Introducing a new process

- Planning a project

3. Flowchart Symbols and Their Meanings

Flowcharts, regardless of the type, employ symbols as the primary means of communication. No matter what process you want to visualize, a fixed set of primary symbols are used to represent the standard elements in a manufacturing process flowchart template. In addition, lines and arrows are used to depict the flow of activities or present the consequence(s) of a process decision. Below is a table that lists the primary symbols used to denote standard flowchart elements.

There are various flowchart shapes used for drawing different types of flowcharts. Each flowchart symbol has its own meaning and context where it is used appropriately. However, whether you want to read a flowchart or try to make one by yourself, knowing the common symbols and what they represent will make things easier. Here, you will see the 5 flowchart symbols that are very popular and commonly used in almost every flowchart.

- The Oval or Pill Shape represents the start/end.

- The Rectangle Shape represents a process.

- The Parallelogram Shape represents the input/output of the information.

- The Diamond Shape represents a decision.

- The Arrow Shape represents the flow of the sequence.

Source: EdrawMax

Not all manufacturing setups are the same. For example, companies that practice lean manufacturing often implement a straightforward setup that is specifically established to minimize waste and delay. By contrast, companies that mass produce a wide variety of products have a relatively elaborate manufacturing setup. For example, a company that manufactures different types of hair products may create multiple flowcharts that include symbols for the machinery used to process each product formula. For this reason, several manufacturing process flowchart templates include specific symbols to represent equipment or a specialized process. To know more about other manufacturing flowchart shapes and symbols, see Manufacturing Flowchart Symbols.

4. Free Manufacturing Process Flowchart Examples

The first step to maximize the use of flowcharts is to determine what kind of diagram fits the process to be visualized. The following examples provide ideas on what type of flowcharts can be used in typical manufacturing scenarios.

- Swimlane Diagram

- Manufacturing Process Flow Diagram

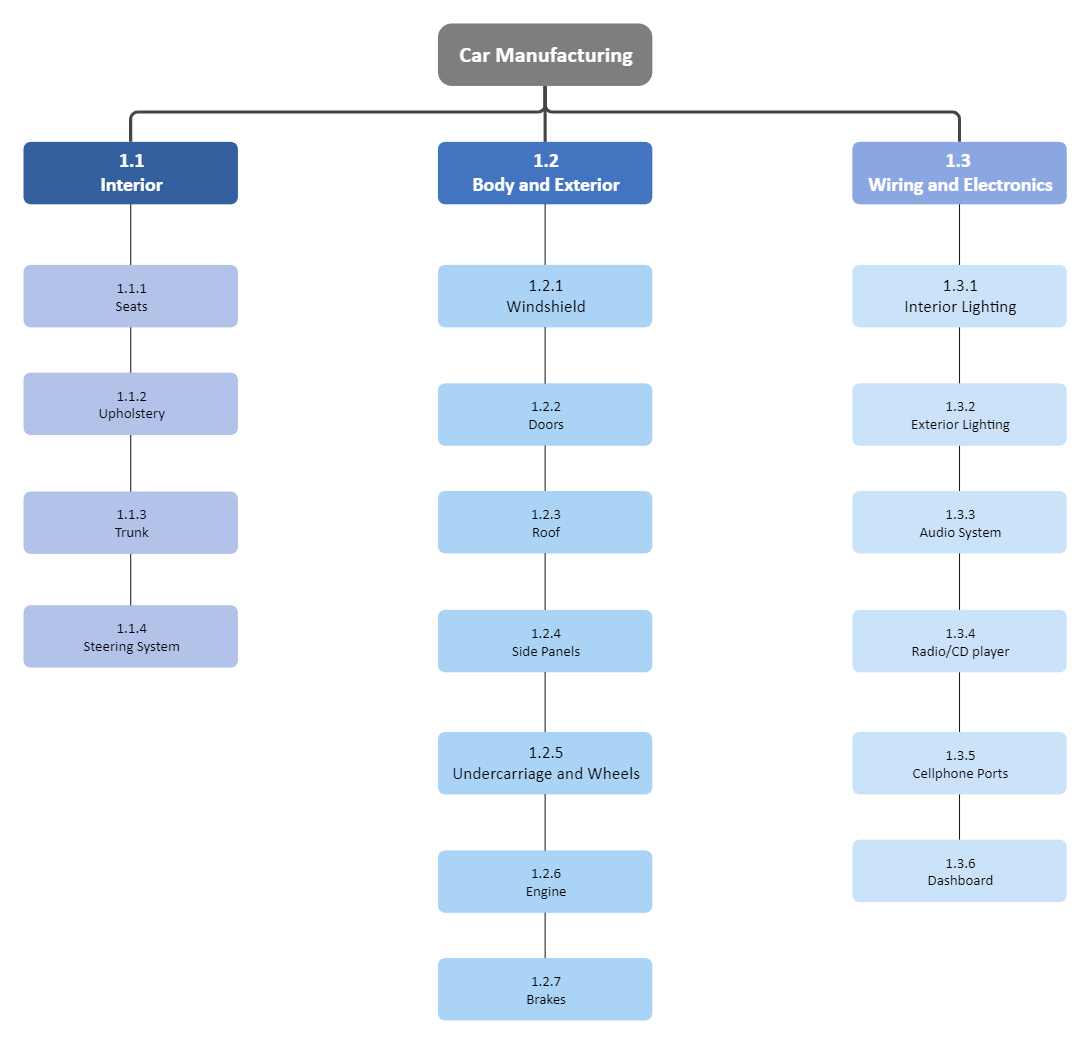

- Car Manufacturing WBS Template

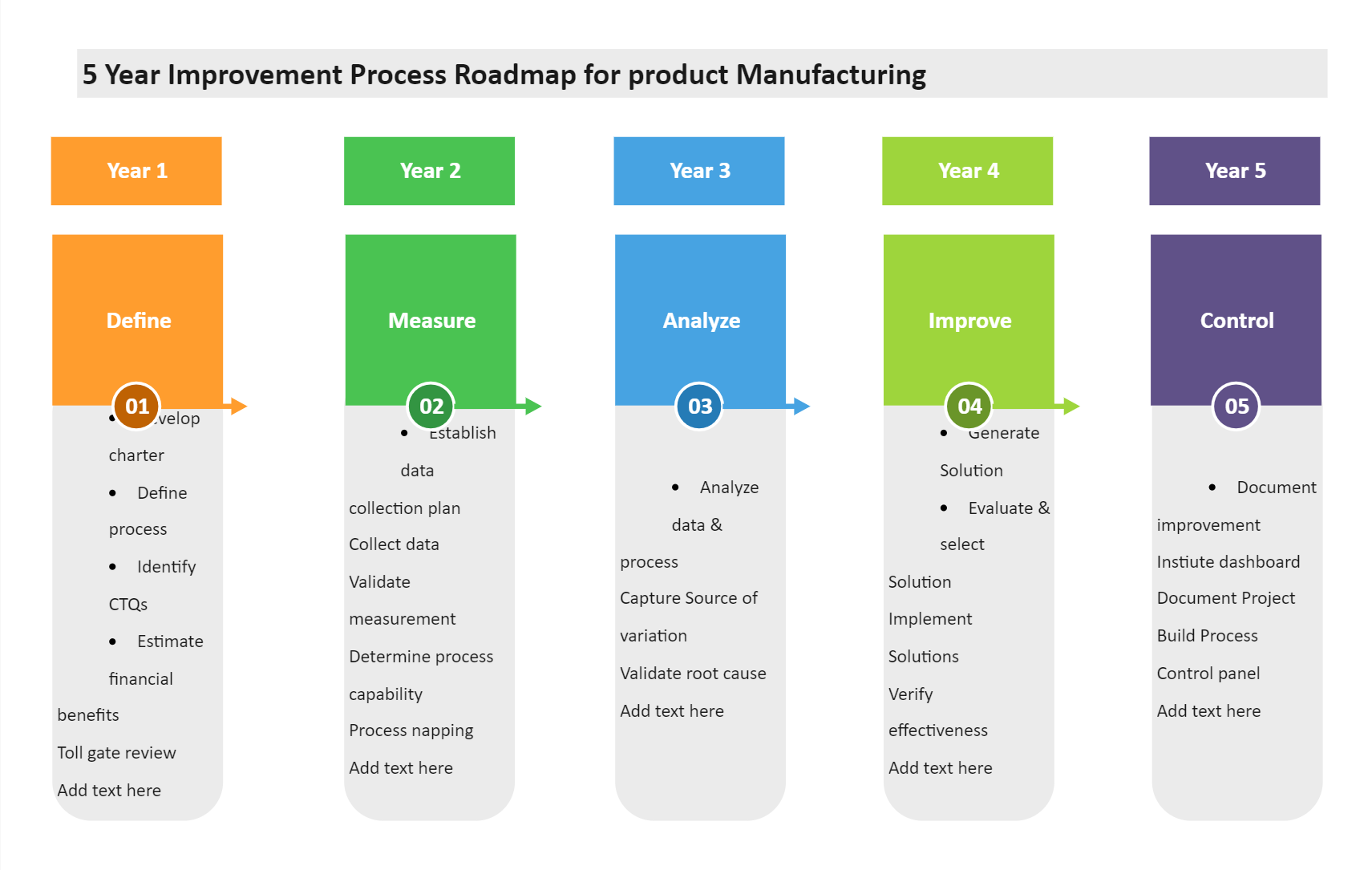

- Product Manufacturing Process Roadmap

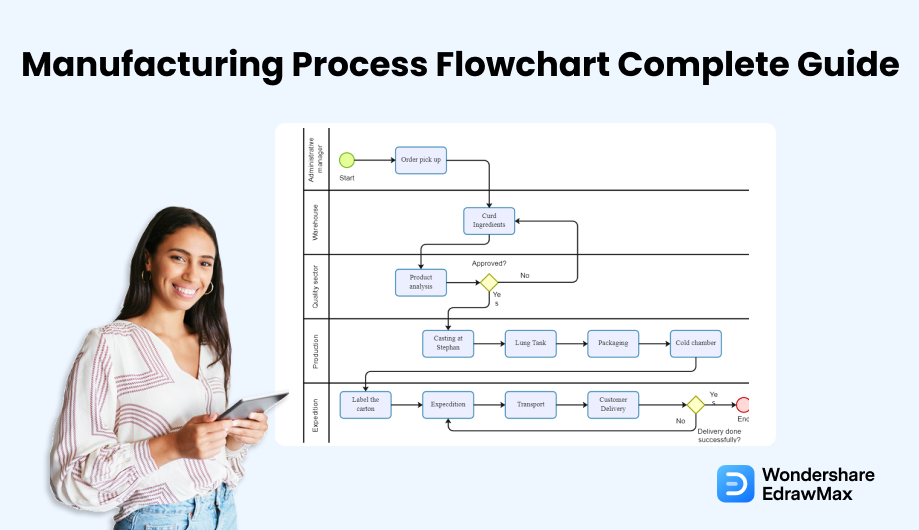

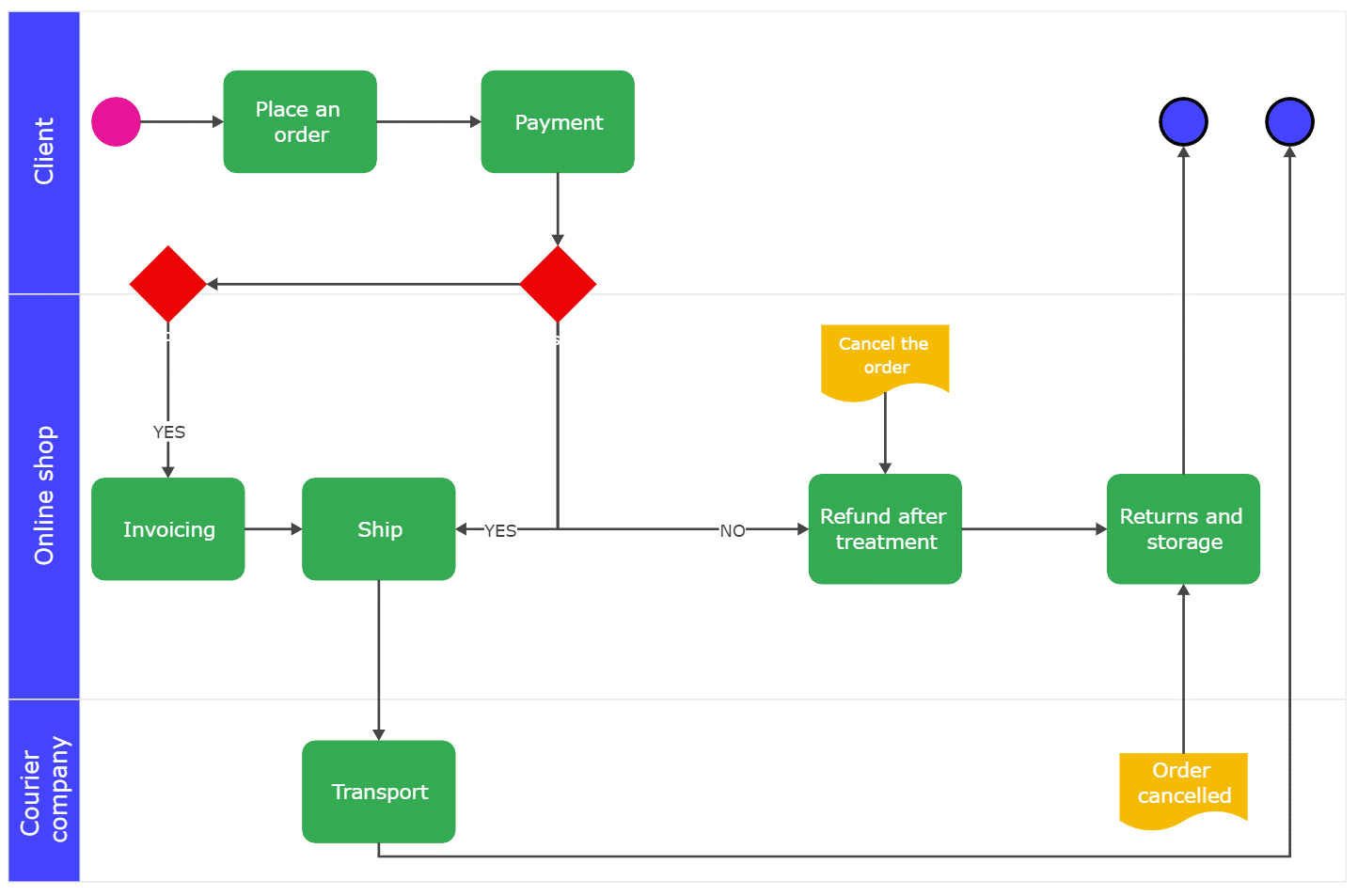

Example 1. Swimlane Diagram

Modeled based on a swimming pool, swimlane diagrams organize the start-to-finish framework of a process based on categories (lanes) that visually divide the responsibilities of a specific process participant. The lanes can be represented by a specific department or employee responsible for completing all subprocesses in the lane.

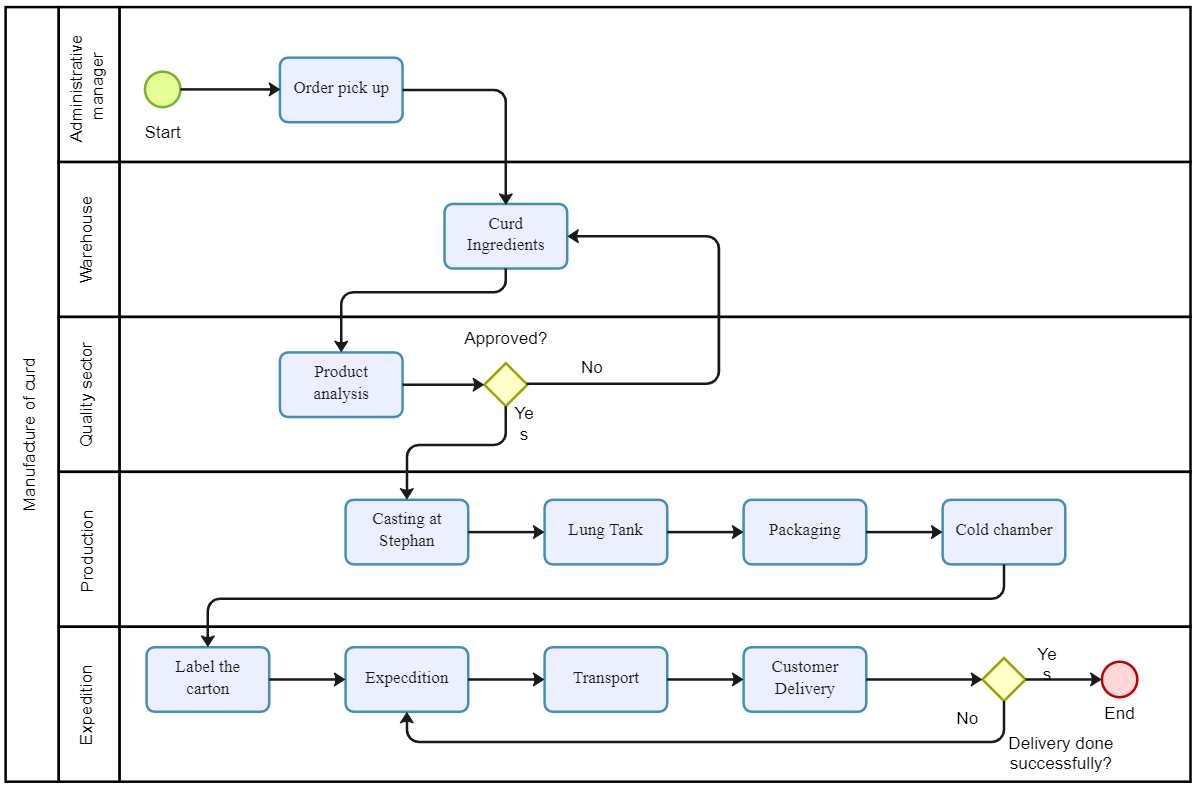

Example 2. Manufacturing Process Flow Diagram

A manufacturing process flow diagram is an extensively used optimization tool used to improve processes and eliminate delays. This type of diagram illustrates the movement of goods from the time the raw materials arrive at the facility to the delivery to the end user.

Example 3. Car Manufacturing WBS Template

Specific to automobile production, this flowchart template shows the breakdown of all activities required to assemble a car. Several automobile companies use this type of diagram to create lean manufacturing process flowcharts to quickly identify improvement points and eliminate bottlenecks in their production operations.

Example 4. Product Manufacturing Process Roadmap

This type of flowchart encompasses the direction and progress envisioned by a company for a specific product or product line. Unlike in the previous example, a process roadmap outlines the initiatives that the management established to sustain and improve the manufacturing process of a product.

5. How to Improve Your Flowchart-making Skills

Creating manufacturing flowcharts does not necessarily require a high level of technical expertise. Here are some tips that you can follow to create a functional manufacturing process flowchart for your organization.

- Set Objectives: You must set specific goals before you create a flowchart. This way, you can select the best type of flowchart and determine how to present it to target users.

- Maintain Consistency: Consistent formatting is a must for flowcharting. This is the reason why flowchart software offers standard manufacturing process flowchart templates.

To create an effective manufacturing process flowchart, make sure that you use coherent symbols and align the components properly. You can also add aesthetic features, such as color coding, to enhance the visual appeal of your flowchart. - Use Only One Page: Contain all elements of your flowchart on one page so that users can easily trace the steps and sequence of activities. If the process is complex, you can partition it into separate individual flowcharts.

- Customize: It is highly recommended that you customize the attributes of your flowchart based on your target users. For example, you can use shapes and symbols to explain the process to a non-technical audience or you can add technical content when presenting your diagram to technical audience.

6. Conclusion

With the advent of technology, people can now select from a wide array of flowcharting software and programs to create manufacturing process flowcharts. All one need is a first-hand experience of the process and good communication skills to ensure that relevant information and reminders can be effectively communicated to the people involved.

As a versatile flowcharting tool, EdrawMax provides a wide selection of manufacturing process flowchart templates. Users can create standard flowcharts by using these templates or make custom diagrams based on their requirements. Explore the features of EdrawMax to start your flowcharting journey in a convenient and enjoyable manner.

Flowchart Complete Guide

Check this complete guide to know everything about flowchart, like flowchart types, flowchart symbols, and how to make a flowchart.

You May Also Like

Business Plan Flowchart Complete Guide

Knowledge

Accounting Flowchart Complete Guide

Knowledge