Walls go beyond being mere dividers. They play a critical role as structural elements that support loads, offer protection against external threats, ensure insulation from heat and sound, and enhance the aesthetics of buildings. However, the diversity in their functions, materials, designs, and benefits sets different wall types apart in construction.

This article thoroughly explores the distinctions among prevalent wall varieties, illuminating their unique characteristics, applications, and contributions to the broader construction landscape. From load-bearing walls to non-load-bearing walls and various finishes, understanding the nuances of these components is essential for architects, builders, and enthusiasts alike.

Load Bearing Walls

Load-bearing walls play a crucial role in supporting the weight of a building's roof, floors, and other structural elements, ensuring the transfer of this load to the foundation for stability and strength. Typically constructed from robust materials like bricks, stones, concrete, or wood, these walls demand meticulous planning and execution due to their substantial weight-bearing responsibilities.

Masonry Walls

One prominent example of load-bearing walls is the masonry wall, composed of individual units such as bricks, blocks, or stones bonded together with mortar. Renowned for durability and fire resistance, masonry walls offer versatility in shaping and patterning, contributing strength and aesthetic appeal to a structure.

Precast Concrete Walls

Another notable type is the precast concrete wall, crafted from concrete panels produced in a factory and later transported for on-site assembly. This method ensures a swift and efficient installation process, delivering high-quality results with uniformity.

Stone Walls

Whether fashioned from natural or artificial stones and assembled through dry-stacking or mortar binding, they stand out for their attractiveness, weather resistance, and seamless integration with the surrounding environment.

Engineering Brick Walls

Constructed using specially designed engineering bricks, they excel in high-strength applications, boasting low water absorption and resistance to frost and chemicals. Ideal for harsh conditions such as dampness, pollution, or erosion, these walls epitomize resilience and longevity in challenging environments.

Pre-Panelized Load-Bearing Metal Stud Walls

Pre-panelized load-bearing metal stud walls represent a cutting-edge solution in modern construction. Engineered for strength and efficiency, these walls utilize pre-assembled metal stud panels, streamlining the building process. The use of metal ensures durability, corrosion resistance, and a lightweight yet robust structure.

Perhaps, load-bearing walls, exemplified by these diverse types, showcase the intersection of structural integrity, aesthetic considerations, and adaptability in the construction realm. Their distinctive characteristics and applications underscore the nuanced choices available to architects and builders as they navigate the complex landscape of wall construction.

Non-Load Bearing Walls

Non-load-bearing walls serve a distinct purpose in construction, as they bear only their own weight without shouldering any additional structural loads. Primarily utilized to delineate spaces, create rooms, or establish privacy, these walls are characterized by their use of lighter and thinner materials, including gypsum, plaster, or metal.

Their flexibility and ease of modification make them instrumental in interior design, as they can be adapted without compromising the overall structural integrity of the building.

Partition Walls

A prime example of a non-load-bearing wall is the partition wall, designed to separate rooms or divide expansive spaces into more manageable units. These walls may feature fixed or movable elements, incorporating openings for doors or windows. Materials such as wood, metal, glass, or plastic can be employed in the construction of partition walls, providing a spectrum of design possibilities.

Panel Walls

Panel walls represent another category, constructed from prefabricated panels affixed to a frame. These walls may take on flat or curved configurations, offering diverse finishes like paint, wallpaper, or tiles. Noteworthy for their lightweight nature and ease of installation, panel walls afford customization to meet various aesthetic and functional requirements.

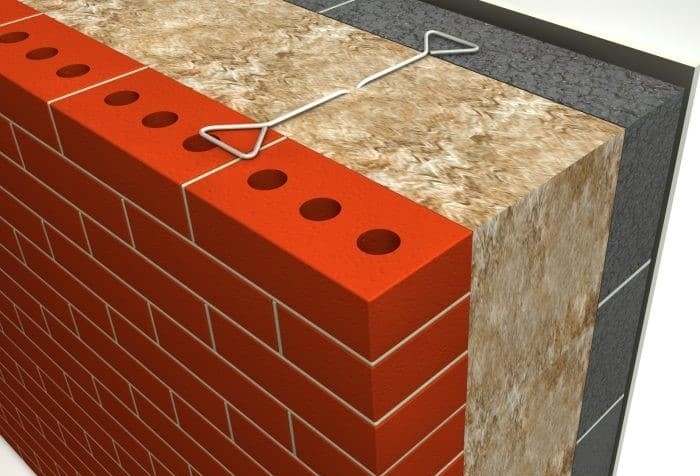

Cavity Walls

Cavity walls are characterized by a hollow space between two layers of masonry or concrete, contributing to enhanced thermal and sound insulation. This design also serves to safeguard the inner layer from moisture infiltration. The cavity can be further optimized with the inclusion of insulation materials like foam or fiberglass, augmenting the wall's performance in terms of energy efficiency.

Shear Walls

Shear walls play a critical role in resisting lateral forces, such as those induced by wind or seismic activity. Typically reinforced with steel bars or mesh, these walls are strategically connected to both the foundation and roof, imparting stiffness and stability to the structure. Their presence mitigates the risk of collapse or damage during adverse conditions, reinforcing the overall resilience of the building.

Indeed, non-load-bearing walls encompass a diverse array of types, each designed to fulfill specific functions within the construction landscape. Their lightweight construction, adaptability, and specialized roles contribute to the intricate tapestry of modern architectural design and construction practices.

Brick Walls

The term "brick walls" encompasses both load-bearing and non-load-bearing walls. In the context of non-load-bearing walls, bricks are arranged to form partitions or enclosures without carrying structural loads. These walls contribute to spatial organization and interior design, often incorporating various brick patterns for visual interest.

Wall Finishes

Wall finishes constitute the concluding layers or coatings applied to wall surfaces, serving to enhance visual appeal, bolster durability, and improve functionality. These finishes fall into two primary categories: faced and veneered.

Faced Walls

A faced wall is characterized by the attachment of decorative or protective materials such as brick, stone, or metal to its outer surface. The primary purpose of faced walls is twofold – they contribute to the aesthetic enhancement of buildings while simultaneously safeguarding the underlying structure from weathering and potential damage. This method allows architects and builders to achieve a harmonious integration of style and resilience in their designs.

Veneered Walls

On the other hand, a veneered wall boasts a thin layer of materials like wood, stone, or plastic, securely affixed to its surface through gluing or nailing. Veneered walls play a crucial role in creating a uniform and sophisticated appearance for buildings. Furthermore, they offer the advantage of concealing any imperfections or irregularities present in the base wall, resulting in a polished and flawless finish.

In fact, the choice between faced and veneered wall finishes represents a nuanced decision in architectural design, where considerations of both aesthetics and practicality converge to yield a visually pleasing and structurally sound final product.

What You Also Need To Know to Execute a Construction Project?

Integral to any structure, walls exhibit diversity in types, sizes, shapes, and materials, playing a pivotal role in the construction of homes, offices, or towering skyscrapers. Familiarizing oneself with the distinct characteristics of various wall types is essential in selecting the optimal choice for a construction endeavor.

Understanding the intricacies of construction elements such as wall details lays a solid foundation for anyone involved in the field. However, knowledge alone is not sufficient. The effective application of this knowledge relies heavily on the adept use of tools.

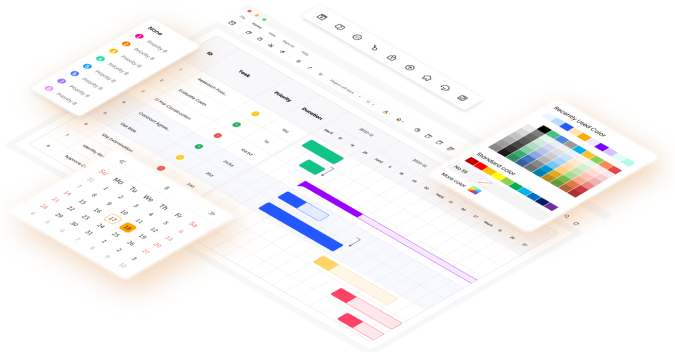

For example, project management software in construction is crucial, ensuring streamlined communication, efficient resource allocation, and accurate progress tracking. It enhances collaboration, minimizes delays, and fosters organization, ultimately optimizing project timelines and budgets. In the dynamic construction environment, such software is indispensable for successful and well-managed projects. So if you are interested, give it a shot today and see if the result will surprise you.

A professional Gantt chart tool to plan, manage and track your projects, process and resources.