Trusted By Over 30 Million Users & Leading Brands

Why EdrawMax to Make Your Fault Tree Analysis?

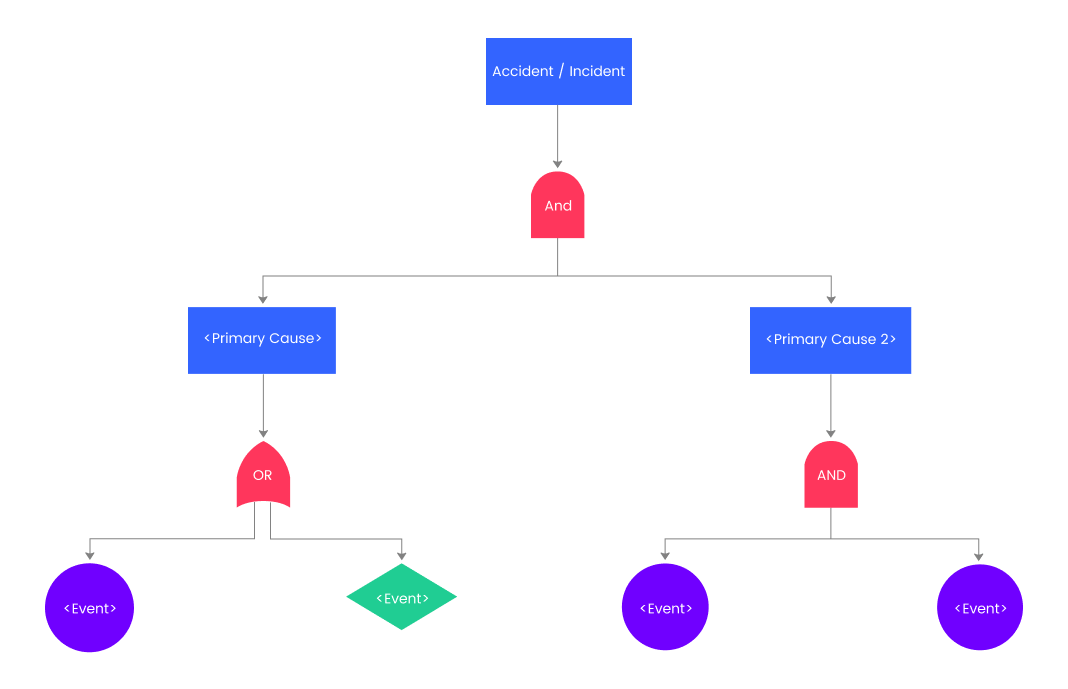

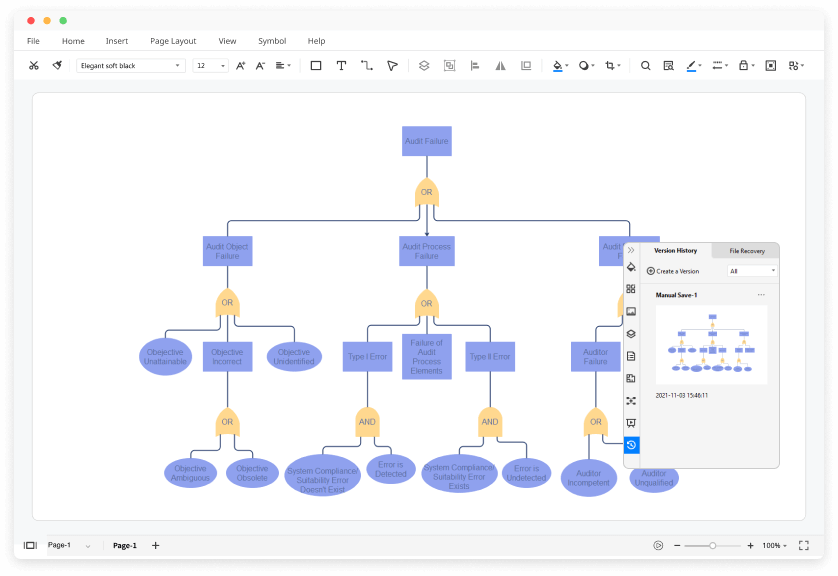

Identify the potential cause of failure

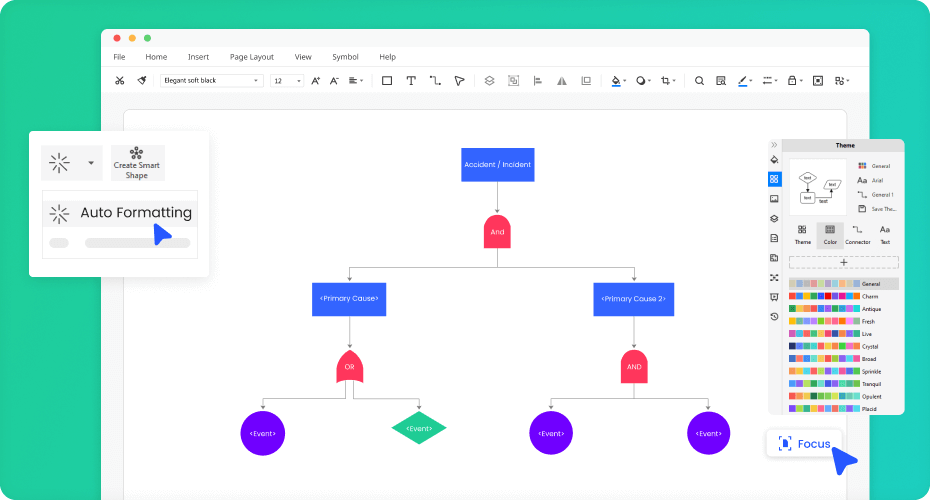

Performing fault tree analysis is a breeze

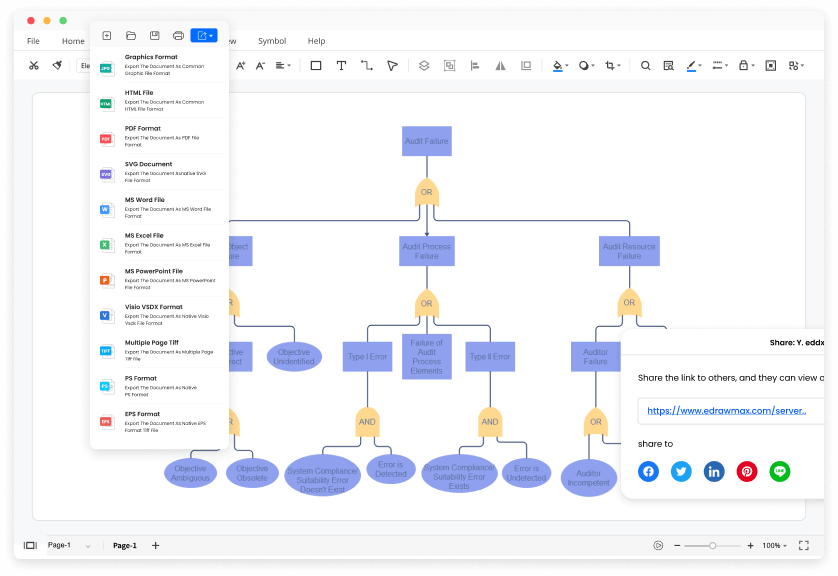

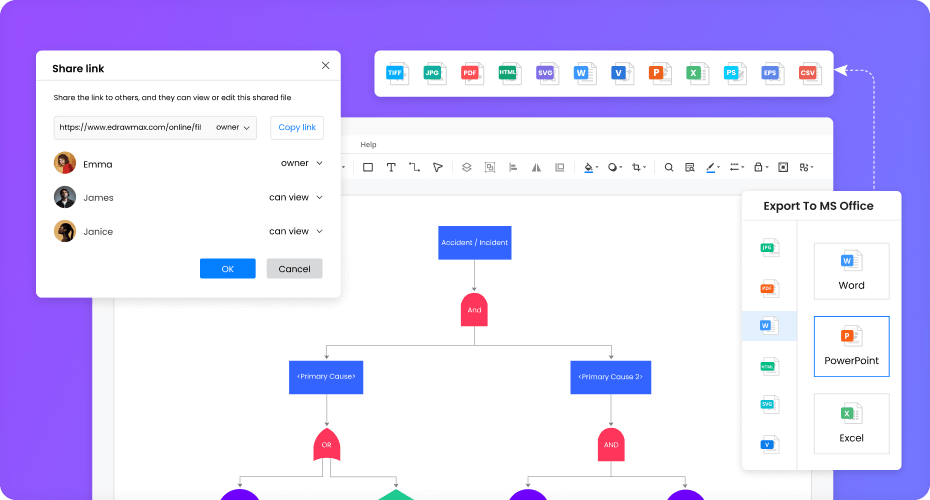

EdrawMax lets you share the work

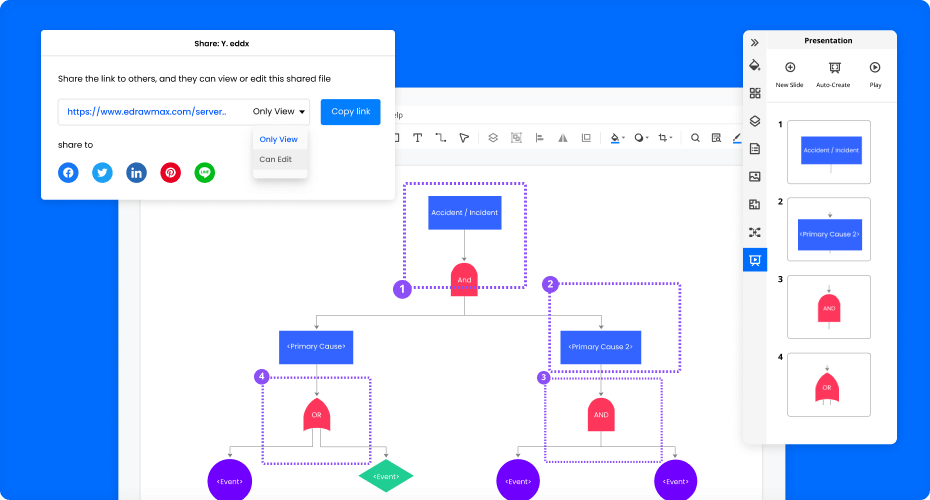

Present and collaborate confidently

More Features Of Fault Tree Analysis Software

Visio files import and export

Customized fonts and shapes

Insert images and attachments

Infinitive canvas

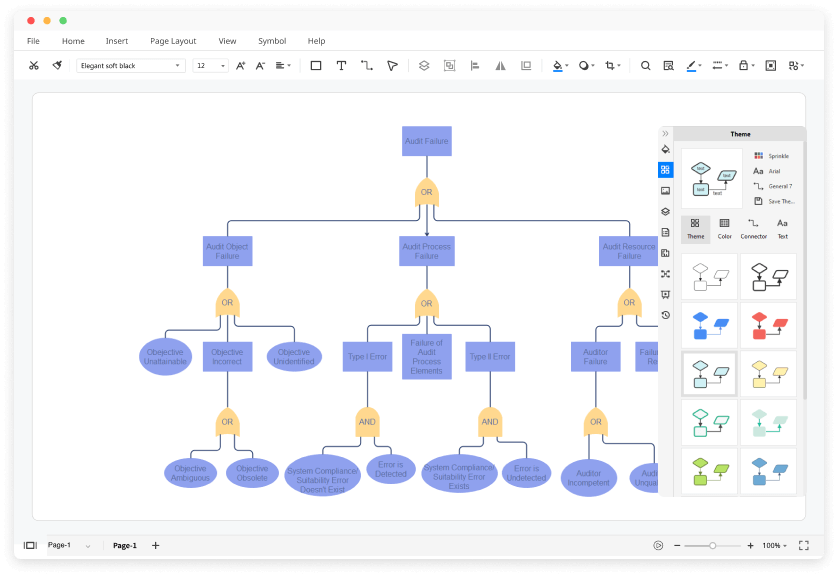

Various color theme

File encryption and file backup

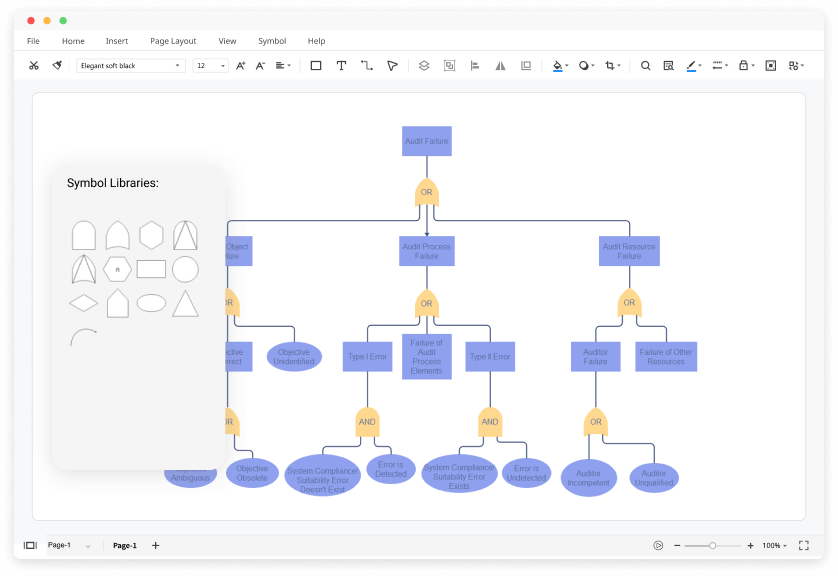

How to Make a Fault Tree Analysis?

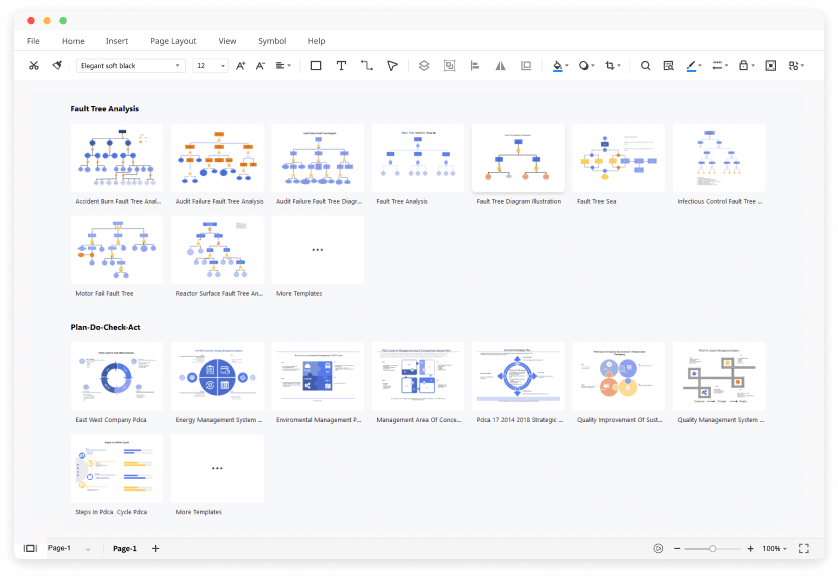

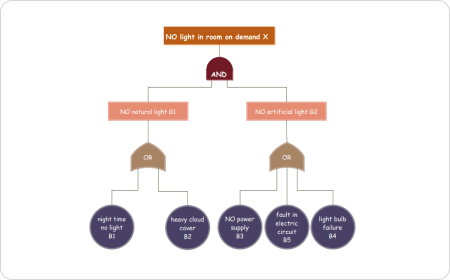

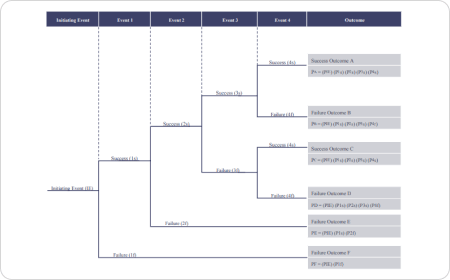

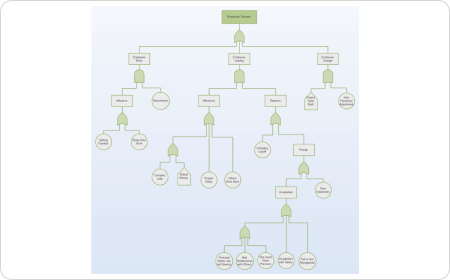

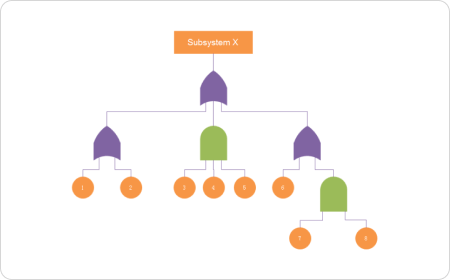

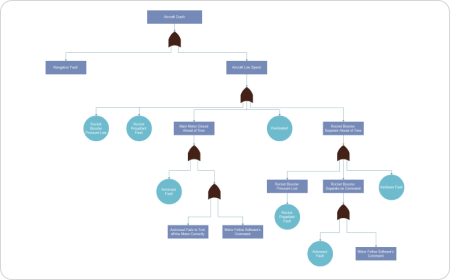

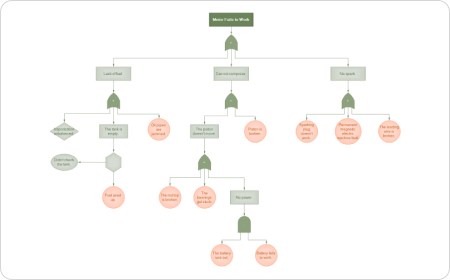

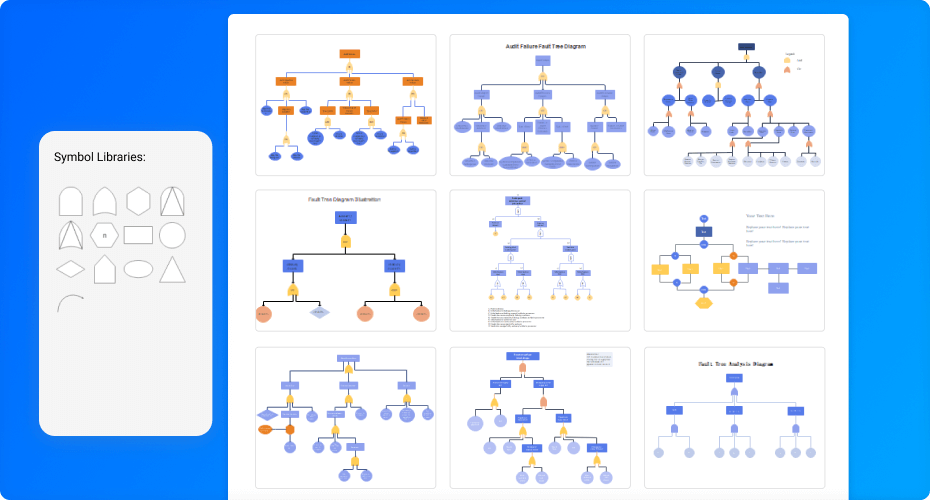

Edraw Fault Tree Analysis Templates

Fault Tree Analysis FAQs

Does EdrawMax have any free fault tree analysis templates?

Except for the pre-made fault tree analysis templates in EdrawMax, you can download and customize templates from our Template Community. All the community-made templates are free to use for Edrawers.

How can I share my fault tree analysis with others who don't use EdrawMax?

When your fault tree analysis is complete, you can post it on social media, publish on Edraw Template Community, or export the file as Word, Excel, PowerPoint, Visio, PDF, SVG, PNG and JPG. EdrawMax is dedicated to delivering a superior user experience.

How can I find fault tree analysis symbols that I need?

No worries. You can find fault tree analysis symbols by opening and searching in the preset symbol libraries of EdrawMax.

How can I create a fault tree analysis from scratch?

You can create a fault tree analysis from scratch by dragging and dropping symbols from the libraries and customizing colors, fonts, lines, etc. All the symbols in EdrawMax are vector, editable, and catered to different types of fault tree diagrams.

Is EdrawMax's fault tree analysis maker free?

YES! It is free to create different fault tree diagrams in EdrawMax. There are free templates, symbols, and easy-to-use editing tools for making fault tree diagrams. Just download it and try EdrawMax now. You will love it right now.

More Resources

Unlock your diagram possibilities by exploring more diagram makers here.

Find more ideas, tips and knowledge to help create fault tree analysiss.

Need help? Find the instruction or contact support here.