How to Create a Value Stream Map (VSM)

- Part 1: What is Value Stream Map?

- Part 2: Why a Value Stream Map is important?

- Part 3: How to Make a Value Stream Map Effortlessly?

- Part 4: An Introduction to Value Stream Map Terms Meaning

- Part 5: Tips for Effective Value Stream Mapping

- Part 6: Features Which Make EdrawMax Outstanding

- Part 7: Value Stream Map Examples

Part 1: What is Value Stream Map?

The process of going from the creation of a product to delivering it to the customer involves a lot of steps, departments, and procedures. Value stream mapping is used by project managers to visualise these steps in order to analyse their processes and improve them.

One of the key advantages of a value stream map is its ability to show the flow of information from one step, or one department, to another. It also allows team members to identify wasteful steps and come up with solutions to iron them out. By doing so, you can identify the steps with the greatest benefit to your project, thus ensuring future workflows are more efficient.

Part 2: Why a Value Stream Map is important?

- It provides optimum value to the customer through a complete value creation process with minimum waste.

- It strengthens the gains by providing vision and plans which connect all improvement activities. It allows you to see waste and to plan how to eliminate it.

- It offers a direct path to process optimization and an operation that is assured long-term survival.

Part 3: How to Make a Value Stream Map Effortlessly?

Step 1: Start EdrawMax.

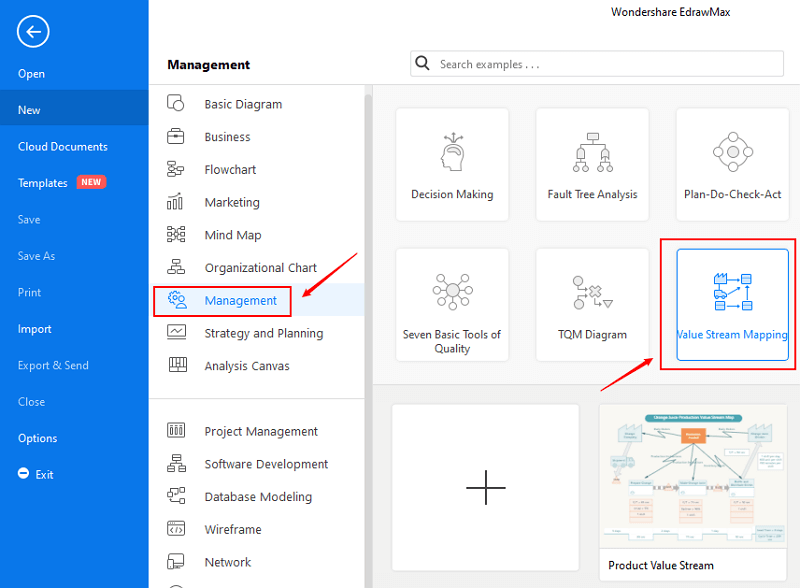

Step 2: Navigate to [New]>[Management]>[Value Stream Mapping]

Step 3: Select one value stream map template to edit on it or click the [+] sign to start from scratch.

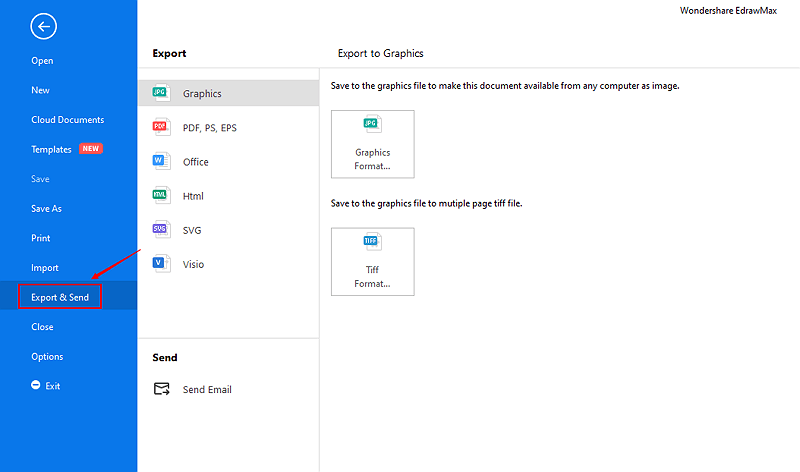

Step 4: You can export the file to Graphics, PDF, editable MS Office file, SVG and Visio vsdx file.

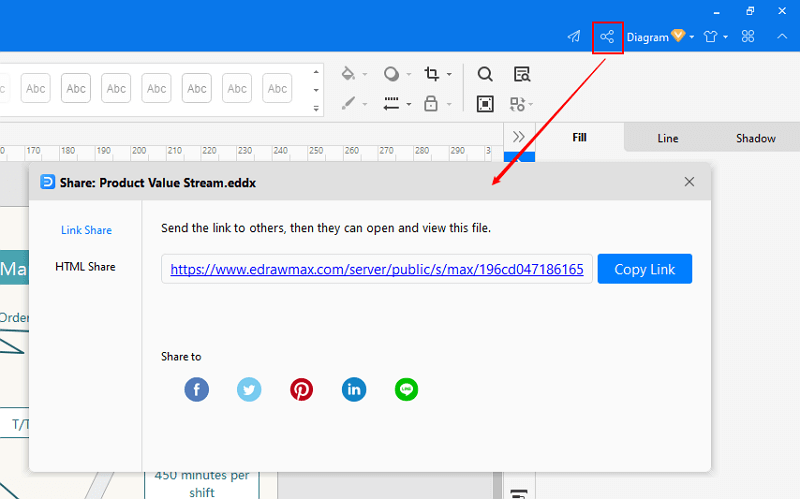

Step 5: And you can share your diagram with others via social media and online website page.

Part 4: An Introduction to Value Stream Map Terms Meaning

- C/T (Cycle Time): The time required to complete a single unit of production.

- C/O (Changeover Time): The non-value added time required to convert a line from one product to another.

- FTT (First Time Through): Percentage of jobs that are complete and accurate the first time that they are processed.

- VA (Value Added): Any part of the production process that improves the product for the customer.

- NVA (None Value Added): Refers to activities that don't contribute to the product or the process and should be eliminated.

- T/T (Takt Time): The average unit production time needed to meet customer demand.

- L/T (Lead Time): Total time required to manufacture a product.

- Capacity: A metric that indicates how many parts per day your slowest process can handle.

Part 5: Tips for Effective Value Stream Mapping

- Get familiar with the basic process steps. This will help you understand the activities and identify crucial path and bottlenecks.

- Choose the major streams that matters. Identify the processes that need to be improved most to impact organizational performance.

- Use standard value stream symbols and icons so that others who trained in value stream mapping could understand.

- Don't do it alone. Organize a cross-functional team to gather information, analyze part flow, draw the map together.

- Don't ignore data when you collect information.

Part 6: Features Which Make EdrawMax Outstanding

- It has advanced and user-friendly drawing techniques which will greatly enhance your productivity.

- A set of nice looking themes help you make visually pleasing drawings with simple clicks. You don't have to be professional in designing.

- Lots of pre-made templates available to use. All documents are vector graphic files with high clarity and available for reviewing and modifying.

- A set of smart tools are provided for automatic formatting. You can easily arrange, rotate, group and align objects.

- Edraw offers various customization options, using which you can adjust line width, line color, line style, font size, font style, text color, and much more.

- Easy to add photos, images and edit text fields.

Part 7: Value Stream Map Examples

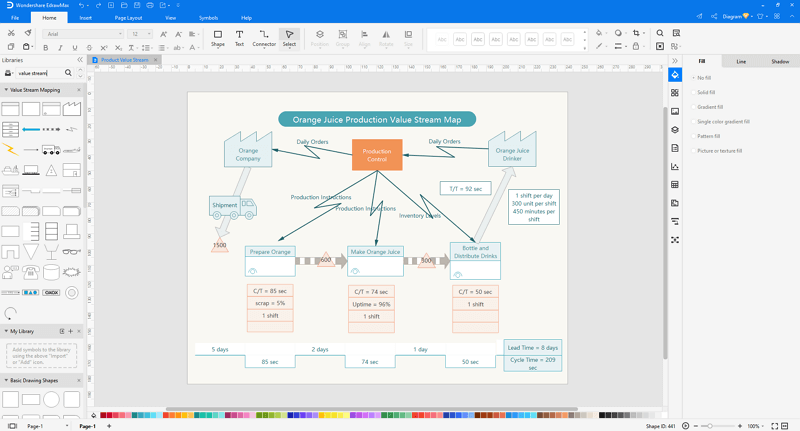

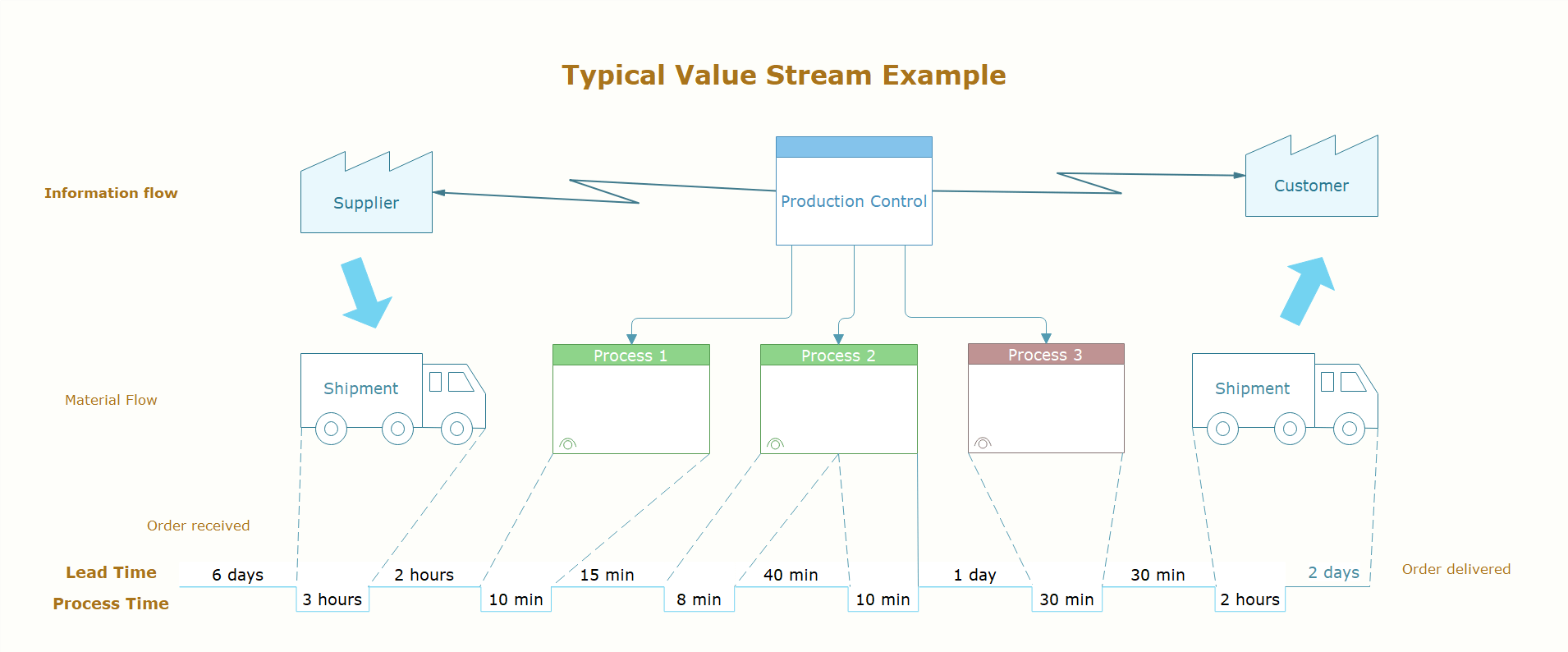

Example 1: Typical Value Stream Example

The process of going from the creation of a product to delivering it to the customer involves a lot of steps, departments, and procedures. Value stream mapping is used by project managers to visualise these steps in order to analyse their processes and improve them. In this example, details are provided about the information flow, material flow, lead time, and process time.

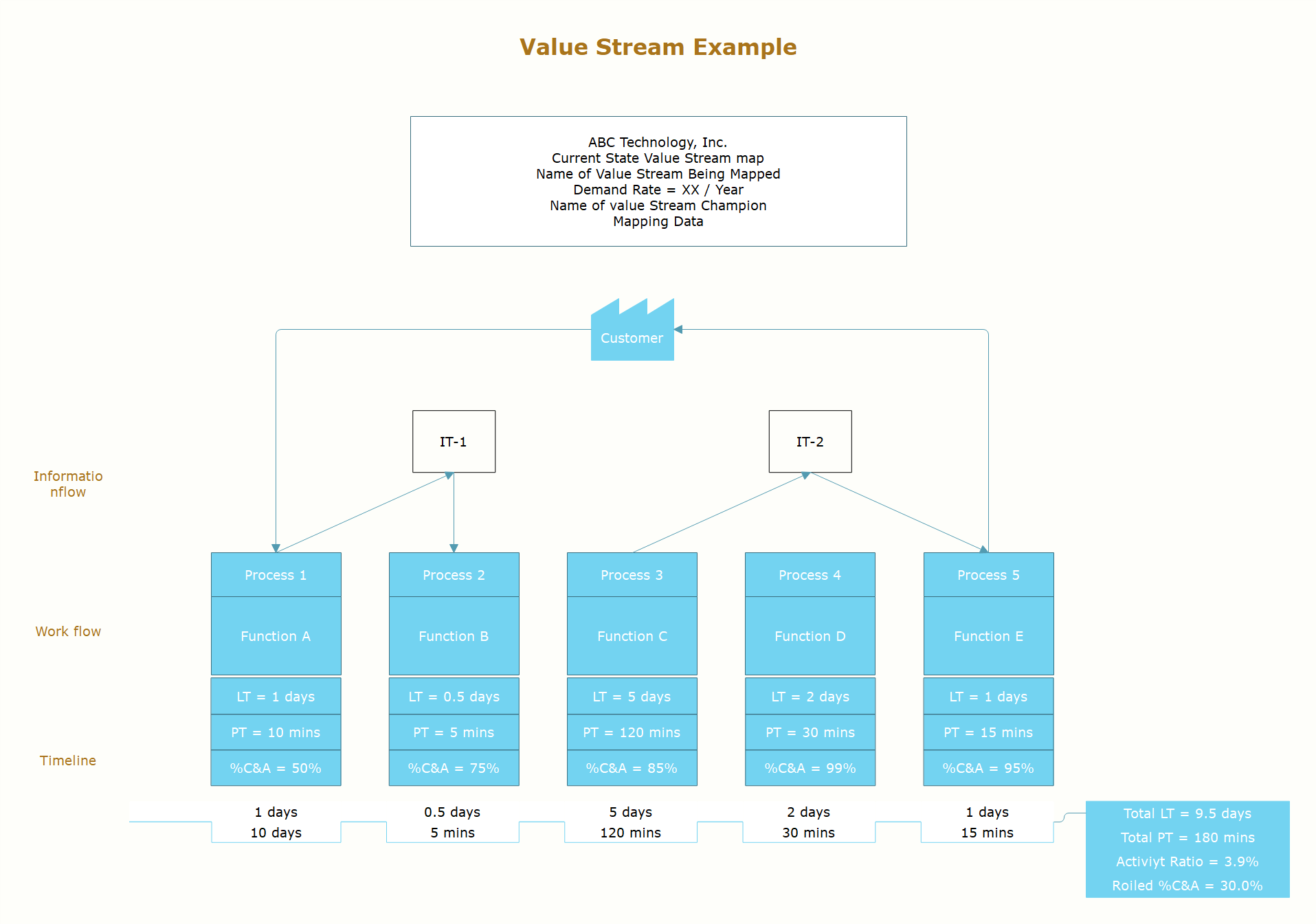

Example 2: Value Stream Example

This value stream map is used to detail the processes of a technology company. The information flow, workflow, and timeline is detailed on the map. Users should focus on time when reading value stream maps. Process time refers to the time needed to perform an action. Lead time refers to the time passed from the moment the task is received to it being moved onto the next stage.

More Related

Easily Learn Value Chains and Value Stream Maps with Pictures